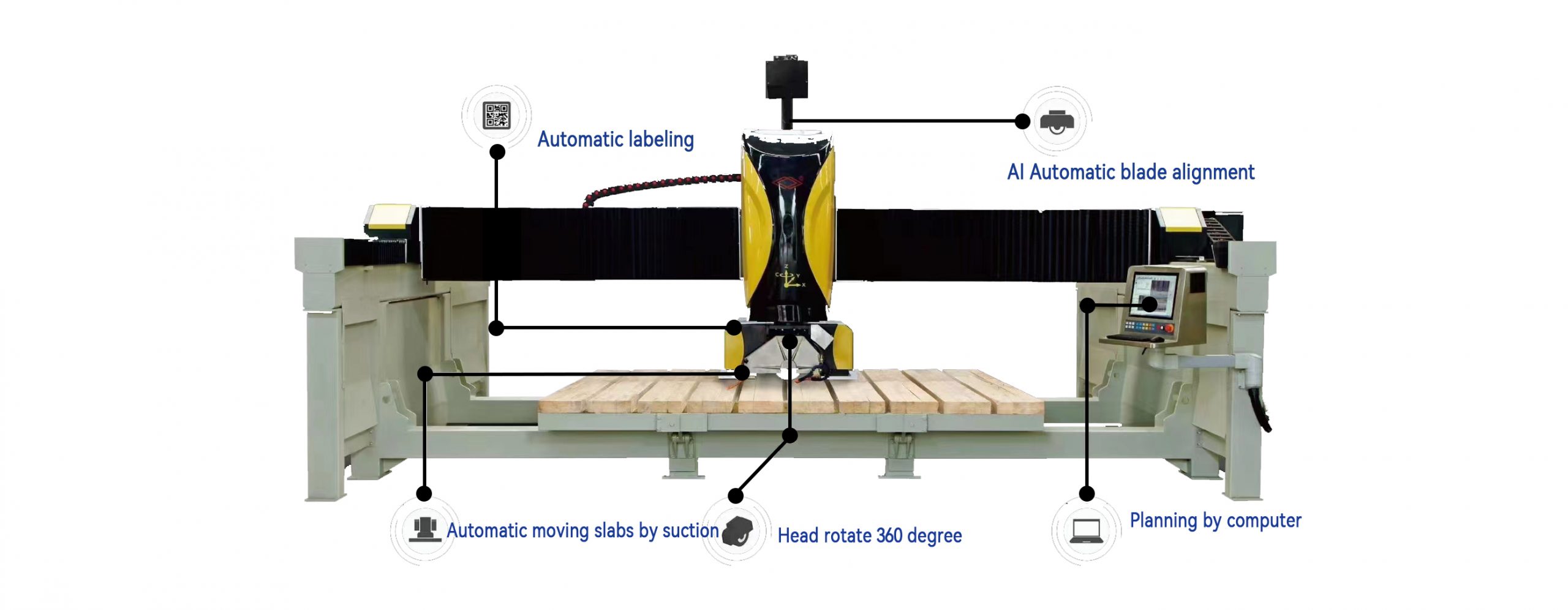

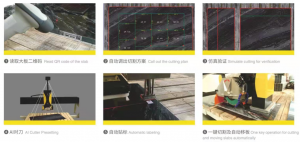

In addition to the functions of traditional bridge cutting machines, the Intelligent Bridge saw also have functions such as automatic labeling, and suction cup to move slabs. Through the intelligent planning software equipped with this machine, the cutting plan can be pre-planned in three ways: automatic optimization of the maximum material use, pattern layout, or manual planning. After importing the plan into the machine, it can be automatically cut with just one click.

TECHNOLOGY PARAMETER

The machine will implement intelligent cutting according to the confirmed plan by the customer, and the entire process includes various necessary functions such as simulation cutting verification, automatic labeling, and automatic moving. It can effectively realize the intelligent production and processing of stone cut-to-size/ tile, achieve confirmation before production, and help promote the industrial transformation and upgrading of the stone industry, ultimately achieving what you see is what you get.

High-fitting components

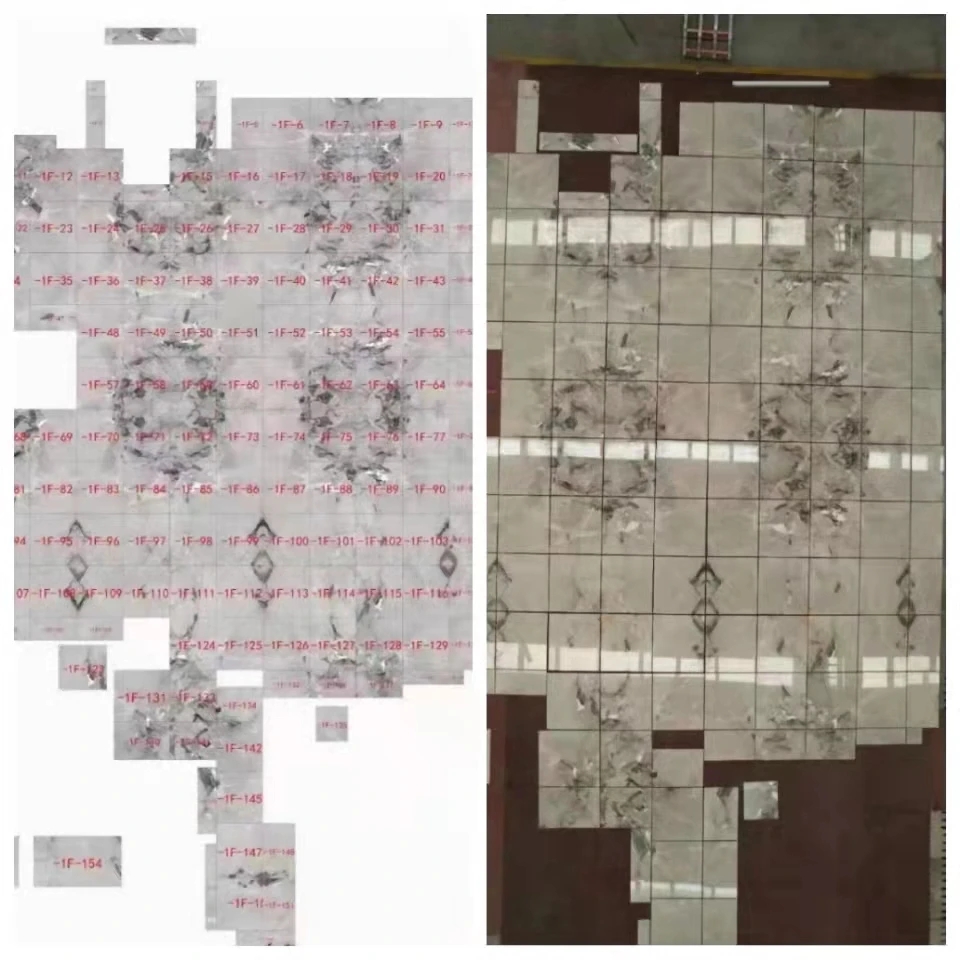

Samples by the Intelligent Saw